Polymer Testing Research

Research Diagram

A major patented development in co-extrusion (DTI sponsored)

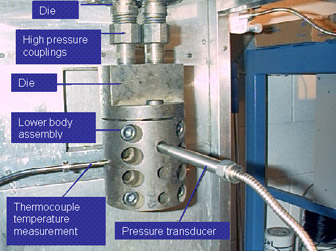

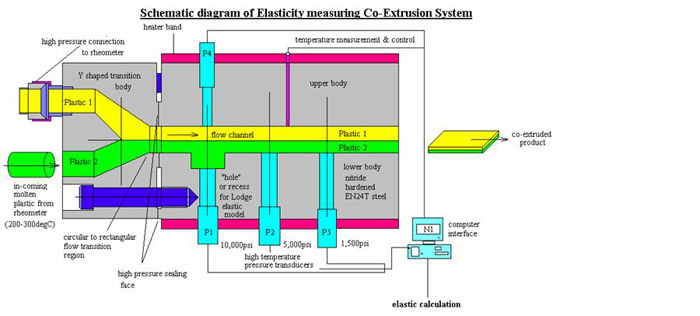

Fleming PTC has patented a rheometer based system (see our patent certificate) for the simulation of co-extrusion. The system allows two dissimilar polymers to be extruded into a common die whereupon measurements of viscosity and elasticity can be made.

The temperature and flow rate of the streams can be changed to simulate conditions representative of those experienced in production. In concert with the rheology, physical compatibility of the two polymers can be easily assessed.

The elastic behaviour of a melted plastic is of great importance during manufacture. Distortion and incorrect product size can occur as the melted plastic attempts to recover from process-induced stretching, often resulting in significant scrap. Both of these problems can be reduced if there is an understanding of the elastic properties of the material.

The specific area of plastics processing for which this research is aimed is co-extrusion. Co-extrusion is the process by which two or more plastics of different type, are extruded together to form one part. Common examples are plastic film or sheet, where each layer has a specific property.

Plastic sheet and film production constitute one of the most prolific uses of plastics today. The elasticity of molten plastics is an area not yet fully understood, and the associated problems of elasticity are multiplied when more than one plastic is involved in the same process; it is for this reason that elastic measurements in co-extrusion are the focus of the on going research.

A system has been designed and patented specifically for the co-extrusion industry in order to provide:

- Elastic measurements on mono or co-extrusions

- Physical compatibility trials using dissimilar polymers

- Small scale assessment of alternative materials

- Off-line assessments of the likely effects of process changes

- Reduced pilot plant time

Processing behaviour of multi phase materials (in association with NPL)

FlemingPTC is working with the National Physical Laboratory (NPL) on a project titled 'Processing behaviour of multi-phase materials MPP7.4'. The project will focus on highly filled materials where the filler is effectively a solid phase, consequently the project should be of interest to many polymer processors using a host of fillers including fire retardants, antioxidants, colour pigments to name just a few.

The work will essentially address the problems of making rheological measurements on filled materials. When using materials which do not slip, it is possible to model the flow off-line using a rheometer, and predict what will happen in complex production dies.

When materials exhibit slip these predictions break down, and to complicate matters the models used to calculate, and thus account for the slip, do not always work. This project will revisit some of these approaches and identify methods of best practice.

Telephone:

01299 251 914

Our postal address:

Fleming

Polymer Testing Ltd,

Holly House

Hartlebury

Kidderminster

DY11 7TE UK