How can rheological measurements help industry?

Rosand RH2200 15mm twin bore capillary rheometer

- 15mm diameter bore

- Ambient to 400 ºC temperature range

- 20KN max force

- 0-500, 0-1500, 0-5000, 0-10,000 & 0-30,000psi pressure transducers

- 1, 0.5, 2 & 0.3mm diameter dies

Rosand RH7-2 & Rosand RH2200

capillary rheometers

- RH7-2 twin bore capillary rheometer

- 12mm diameter bore

- Ambient to 400 ºC temperature range

- 40KN max force

- Slot die attachment

- Co-extrusion die attachment

- Various channel geometries

- 3 pressure transducers for δP measurement

- Conair Desicant Dryer for moisture sensitive materials

- Townson & Mercer Vacuum Oven for drying moisture sensitive polymers

By providing insight into polymer molecular architecture, morphology, chain branching, anisotropic microstructure development, temperature dependence, degradation and stability, elasticity, batch to batch variation, materials selection, matching the material to the process, die design, material modelling, data input for process simulation, effect of filler type, size, size distribution & aspect ratio.......test it, understand it, solve the problem!

Capillary Rheometry

Capillary Dies & Gauges for use with the Rheometer

Most of today's polymer processing operations exploit deformation and flow in order to create the vast range of polymeric products available. A rheometer replicates the deformation and flow regimes typically experienced in extrusion and injection moulding; the ability to replicate the flow remotely is instrumental in process optimisation and material characterisation.

Rheometry is historically associated with viscosity measurement, and whilst this is an important rheological parameter it constitutes only one of a number that are required to yield a comprehensive characterisation. Listed below are some of the other essential parameters:

- Shear Viscosity - Bagley and Rabinowitsch corrected, essential for result integrity and pre-requisite for most die design and flow simulation packages.

Elongational Viscosity - determined via the Cogswell convergent flow model. Elongational viscosity, or the resistance to elongation is known to be sensitive to material structure (MWD and chain branching).

Dissimilar MWD can often be resolved in radioactive and peroxide cross-linked LLDPE's that other techniques (shear viscosity and MFI) are blind to. Branching differences, such as those seen in HDPE and LDPE, can also be differentiated as can changes due to catalyst type using this measurement.

- Wall Slip - often found in PVC, filled and multi-phase suspensions.

- Melt Fracture - a very real problem in film blowing, sheet and pipe extrusion manifesting itself as a surface distortion or sharkskin. Melt fracture is easily detected as pressure fluctuations in capillary rheometry, thus enabling the onset of fracture to be predicted off-line using a small quantity of material.

- Stress Relaxation - specifically for the measurement of yield stress t yield or the no-flow stress and useful in the characterisation of multi- phase suspensions (ceramics) where green strength is of importance; yield stress is indicative of green strength.

- PVT - often used in Injection Moulding simulation software for mould fill prediction.

- Flow Visualisation - rheological characterisation is increasingly being used in flow simulation software such as Compuplast for die\screw design, multi-layer extrusion and film blowing optimisation.

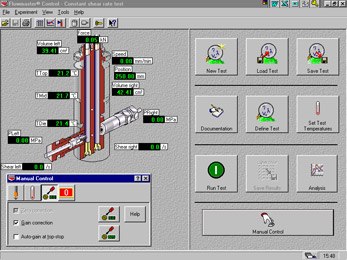

The Rosand Capillary Rheometer FlowMaster Software

Rheology Training and Interpretation

Rheometry training is essential if the best use is to be made of what are very complex instruments. Many field leaders are requesting assistance with tuition on both rheometry fundamentals and the more sophisticated techniques such as wall slip, elongational viscosity and elasticity.

A highly sophisticated technique such as rheometry can often see instruments unused for enough time that operators forget how to use the machine or, personnel leave and new operators have to get up to speed. In both scenarios courses can be tailored to train or retrain key personnel to the level required.

The Benefits of Training include:

- Brushing up on the basics -

Why do we do the Bagley & Rabinowitsch corrections, what is true stress ? - Strange looking results - melt fracture or hardware problems ? Can we publish these results ?

- Train to use sophisticated techniques - elongational viscosity, wall slip, elasticity

- Train to model material data

- Train to input material data into flow simulation software

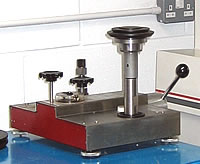

The Budenburg Dead Weight Tester

Pressure Calibration:

- Pressure range: 0.1MPa to 70MPa

- Dual area piston with automatic changeover

Allows highly accurate calibration of pressure transducers. Essential for rheometry since stress and all subsequent calculations are based on pressure. It can be difficult to tell when a pressure transducer is damaged and reading incorrectly without comparing against an known reference. Regular checking and calibration is recommended in order to ensure result integrity.

Telephone:

01299 251 914

Our postal address:

Fleming

Polymer Testing Ltd,

Holly House

Hartlebury

Kidderminster

DY11 7TE UK